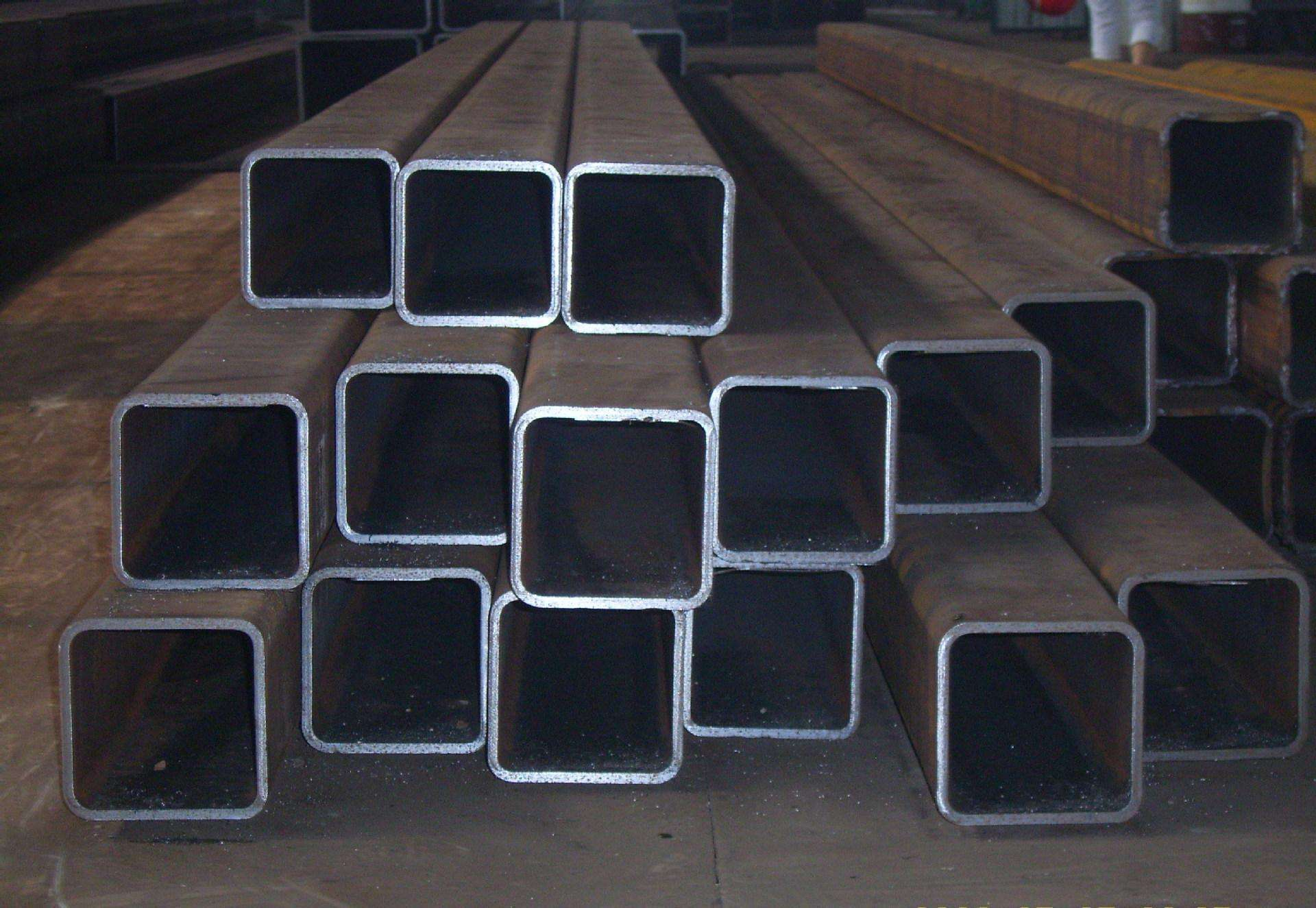

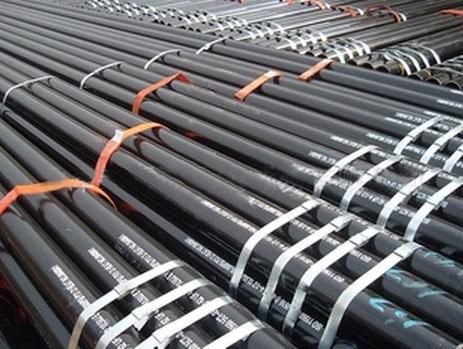

直縫焊管是通過高頻焊接機組或者是通過埋弧焊機組焊接而成。高頻焊接直縫焊管國內(nèi)目前可生產範圍:口徑10-711mm厚度3-25mm。埋(mái)弧(hú)焊直縫焊(hàn)管可生產範圍,口徑:325-1420mm厚度8-25mm。直縫焊管工藝簡單,生產速度快所以它在(zài)城市建設,鋼構工程,輸氣(qì)工程和供排水工程建(jiàn)設方麵起著不可替代的作(zuò)用。所以選擇好優質的直縫焊管是保證工程安全順利進行的必要因素。

Longitudinal welded pipe is welded by high frequency welding machine or submerged arc welding machine. At present, the domestic production range of high frequency welded straight seam welded pipe is 10-711mm in diameter and 3-25mm in thickness. Submerged arc welding straight seam welded pipe can be produced in a range of sizes: 325-1420 mm thick 8-25 mm. Longitudinal welded pipe has simple technology and fast production speed, so it plays an irreplaceable role in urban construction, steel structure engineering, gas transmission engineering and water supply and drainage engineering construction. Therefore, the selection of high quality straight seam welded pipe is a necessary factor to ensure the safe and smooth operation of the project. 在選擇直縫焊管的時(shí)候第一我們要注意材質,一般直縫焊(hàn)管的材質有Q235,16Mn,和L245等等,在我們驗貨的時候首先要確定材質是否合格。第二要(yào)看看(kàn)直縫焊管(guǎn)的壁厚,是否達到要求的壁厚。公差(chà)是(shì)否在國(guó)家要求範圍之內。第三要看焊管(guǎn)表麵(miàn)情況,是否有(yǒu)鏽,鏽的程度,一般黃鏽沒有問題,一般黃鏽都是一層浮鏽,紅鏽稍微嚴重一點(diǎn)。

When choosing straight seam welded pipe, we should first pay attention to the material quality. Generally, the material of straight seam welded pipe is Q235, 16Mn, L245 and so on. When we inspect the goods, we should first determine whether the material is qualified. The second is to see whether the wall thickness of the longitudinal welded pipe meets the required wall thickness. Is tolerance within the scope of national requirements? Third, it depends on the surface condition of welded pipe, whether there is rust or not, the degree of rust, general yellow rust is no problem, general yellow rust is a layer of floating rust, red rust slightly more serious.

但是退火過後也可以(yǐ)在一些不是很嚴格的項目上使用,但是如果是黑鏽(xiù),說明這管子就隻能賣廢鐵了。還有我們要看一下焊管表麵是(shì)否有由,因為(wéi)直縫焊管在生(shēng)產過程中在機組上有可能會沾(zhān)染油漬,最(zuì)後我們要看管子(zǐ)兩頭的斷麵情況是否是圓麵還是有擠壓不規整。還要看下是否有毛刺。經過以上幾種嚴格的檢測手段如果焊管都(dōu)通過,那麽(me)說明管子是合格的。

But after annealing, it can also be used in some less stringent projects, but if it is black rust, it means that the pipe can only sell scrap iron. Also, we need to see if there is any reason for the surface of the welded pipe, because the longitudinal welded pipe may be contaminated with oil stains on the unit during the production process. Finally, we need to see whether the cross-section of both ends of the pipe is round or irregular extrusion. It also depends on whether there are burrs. After the above several strict testing methods, if the welded pipe passes, then the pipe is qualified.