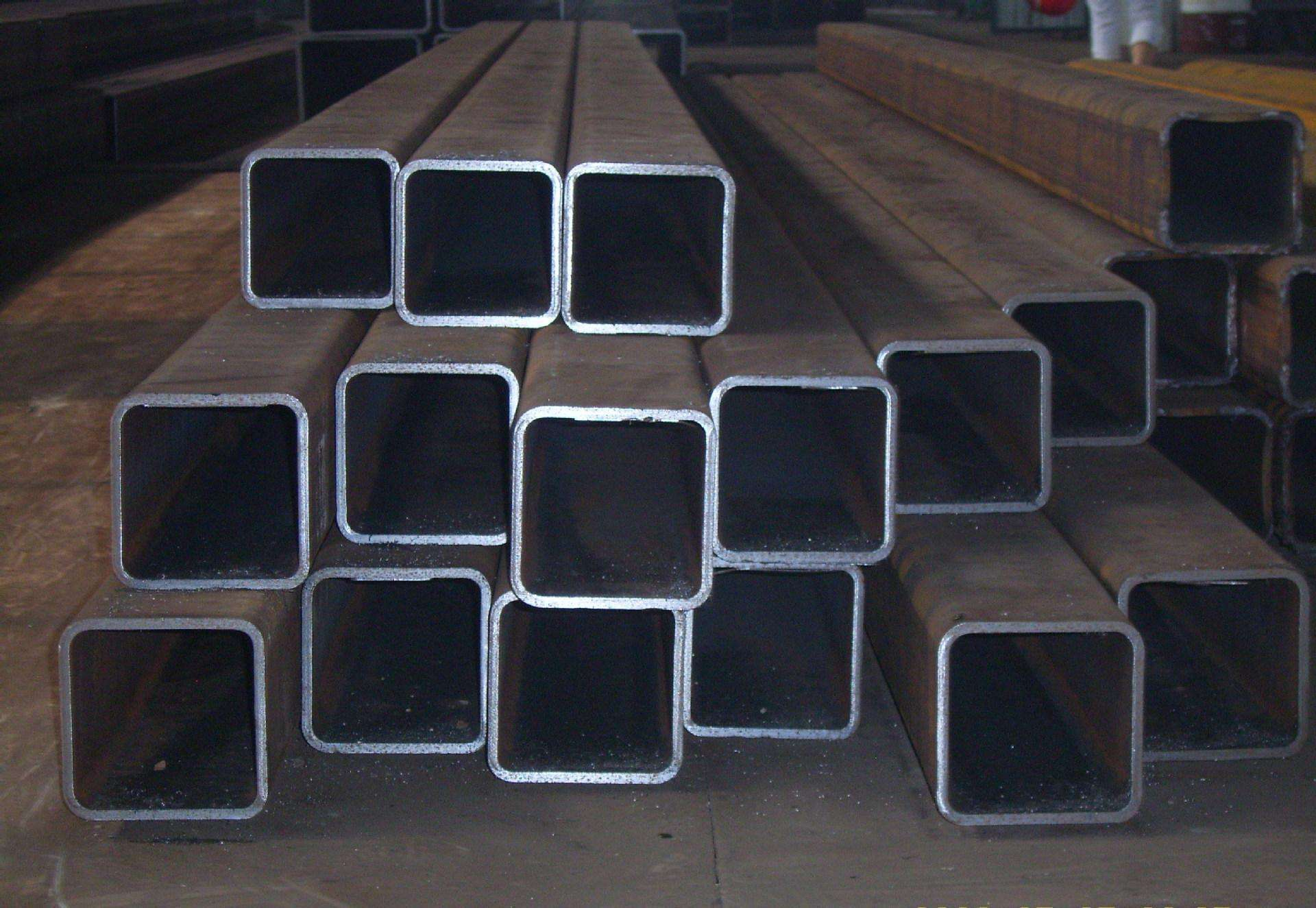

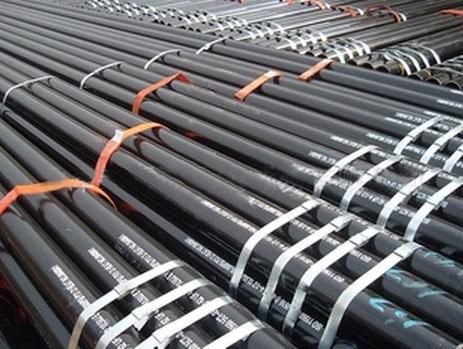

直縫焊管是用鋼板或鋼(gāng)帶經過(guò)彎曲成(chéng)型,然後(hòu)經焊(hàn)接製(zhì)成。按焊縫形式分為直縫焊管和螺(luó)旋焊管(guǎn)。按用(yòng)途(tú)又分為一般焊管、鍍(dù)鋅焊管、吹氧焊管、電(diàn)線套管(guǎn)、公製焊管、托輥管、深井泵管、汽車用管、變壓器管、電焊薄壁管、電焊異型管和螺旋(xuán)焊管。大口徑直縫焊管主(zhǔ)要生產流程說明:

Longitudinal welded pipe is made of steel plate or strip after bending and welding. According to the weld form, it can be divided into straight welded pipe and spiral welded pipe. According to its use, it can be divided into general welded pipe, galvanized welded pipe, oxygen-blowing welded pipe, wire sleeve, metric welded pipe, idler pipe, deep well pump pipe, automobiles pipe, transformer pipe, welded thin-walled pipe, welded special-shaped pipe and spiral welded pipe. Description of main production process of large diameter straight seam welded pipe:

1.板探:用來製造大口徑埋弧焊直縫鋼管的鋼板進入生產線後,首先進行(háng)全板超聲波檢驗;

1. Plate prospecting: After the steel plate used to manufacture large diameter submerged arc welded straight seam steel pipe enters the production line, the whole plate ultrasonic inspection is carried out first.

2.銑邊:通過銑邊機對鋼板兩(liǎng)邊緣進行雙麵銑削,使之達到要求的板寬、板邊平行度(dù)和坡(pō)口(kǒu)形狀;

2. Milling: Double-sided milling of steel plate edges by milling machine to achieve the required width, parallelism and groove shape;

3.預彎邊(biān):利(lì)用預彎機進行板邊預彎,使板(bǎn)邊具有符合要求的曲率;

3. Pre-bending edge: Pre-bending edge with pre-bending machine, so that the edge of the plate has the required curvature;

4.成型:在JCO成型機上首先將預彎後(hòu)的鋼板的一半(bàn)經過(guò)多次步進衝壓,壓成"J"形(xíng),再將鋼板的(de)另一半同樣彎曲,壓成"C"形,最後形成開口的"O"形(xíng)

4. Forming: On JCO forming machine, first half of the pre-bended steel plate is stamped into "J" shape by several steps, then the other half of the steel plate is also bent into "C" shape, and finally the "O" shape of the opening is formed.

5.預焊:使成型後的直縫焊鋼管合縫並采用氣體保護(hù)焊(MAG)進行連(lián)續焊接;

5. Pre-welding: to make the formed straight seam welded steel pipe seam and use gas shielded welding (MAG) for continuous welding;

6.內焊:采用縱列多絲埋弧焊(最多可為四絲)在直縫鋼管(guǎn)內側進行焊接;

6. Internal welding: Longitudinal multi-wire submerged arc welding (up to four wires) is used to weld the inside of the straight seam steel pipe.

7.外焊:采用縱列多絲(sī)埋弧焊在直(zhí)縫埋(mái)弧焊鋼管外側進行焊接;

7. External welding: Longitudinal multi-wire submerged arc welding is used to weld the outer side of longitudinal submerged arc welded steel pipe.

8.超(chāo)聲波檢驗Ⅰ:對直縫焊鋼管內外焊縫及焊縫兩側母材進行100%的檢查;

8. Ultrasound Inspection I: 100% Inspection of the inside and outside welds and the base metal on both sides of the weld of the longitudinal welded steel pipe;

9.X射(shè)線檢查Ⅰ:對內外(wài)焊縫進行100%的X射線(xiàn)工業電視(shì)檢查,采用圖象處理係統以保證(zhèng)探傷的靈敏度;

9. X-ray inspection I: 100% X-ray industrial television inspection of internal and external welds, image processing system to ensure the sensitivity of flaw detection;

10.擴徑(jìng):對埋弧焊直(zhí)縫鋼管(guǎn)全長進行擴徑以提高鋼管的尺寸精度,並改善鋼管內應力的分布狀態;

10. Diameter enlargement: The whole length of submerged arc welded straight seam steel pipe is enlarged to improve the dimensional accuracy of steel pipe and the distribution of internal stress of steel pipe.

11.水壓試驗:在水(shuǐ)壓試驗機上對擴徑後的鋼管進行逐根檢驗以保證鋼管達到標準要求的試驗壓力,該機具有自動記錄和儲存功能;

11. Hydraulic test: The expanded steel pipe is inspected one by one on the hydraulic test machine to ensure that the test pressure meets the standard requirements. The machine has the function of automatic recording and storage.

12.倒棱:將檢驗合格後的鋼管進行管端加工,達到要求的管端坡口尺寸(cùn);

12. Chamfering: The qualified steel pipe will be processed to meet the required pipe end groove size;

13.超(chāo)聲波檢驗Ⅱ:再次逐(zhú)根進行超聲波檢驗(yàn)以檢查直縫(féng)焊鋼管在擴徑、水壓後可能產(chǎn)生的(de)缺陷;

13. Ultrasound Inspection II: Ultrasound Inspection is carried out one by one again to inspect the possible defects of longitudinal welded steel pipe after diameter enlargement and hydraulic pressure.

14.X射線(xiàn)檢查Ⅱ:對擴徑和水壓試(shì)驗後的鋼管進行X射線工業電視檢查(chá)和管端焊縫拍片;

14. X-ray inspection II: X-ray industrial television inspection and photography of weld seam of pipe end after diameter enlargement and hydraulic test;

15.管端磁粉檢驗:進行此項檢查以發現管端缺陷;

15. Tube end magnetic particle inspection: this inspection is carried out to find the defect of the tube end;

16.防腐和塗層:合格後的鋼管根(gēn)據(jù)用戶要求進(jìn)行防腐(fǔ)和塗層。

16. Anti-corrosion and coating: qualified steel pipes are anticorrosive and coated according to user's requirements.