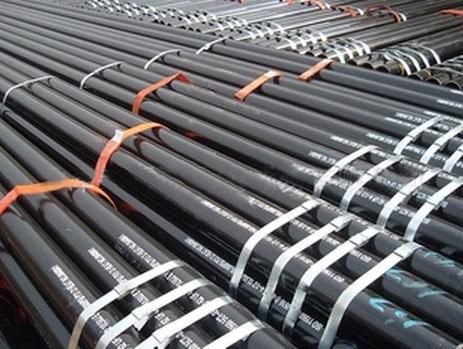

焊管是燃氣管(guǎn)道中的(de)常見管材,直徑大於426mm(或508mm)的焊管一般被稱(chēng)為(wéi)大口徑焊管,按照焊接成管方式(shì),可(kě)分為螺(luó)旋焊管和直縫焊管兩(liǎng)種(zhǒng)。螺旋焊管是將(jiāng)低碳碳(tàn)素結構鋼或低合金結構鋼鋼帶(dài)按一定的螺旋線的角度(又叫成型角)卷(juàn)成管坯,然後(hòu)將管縫焊(hàn)接起來製成,它可以用較窄的帶鋼生產大直徑的鋼(gāng)管。螺旋焊管(guǎn)主要(yào)是螺旋埋弧(hú)焊(hàn)管(SSAW),在我國廣泛用(yòng)於各(gè)種燃氣管(guǎn)道的建設(shè),其規格用外徑*壁厚表示。螺旋焊管有單麵焊的(de)和雙麵焊的,焊管應保證水壓試驗、焊縫(féng)的抗拉強度和冷彎性能(néng)要符合規定。

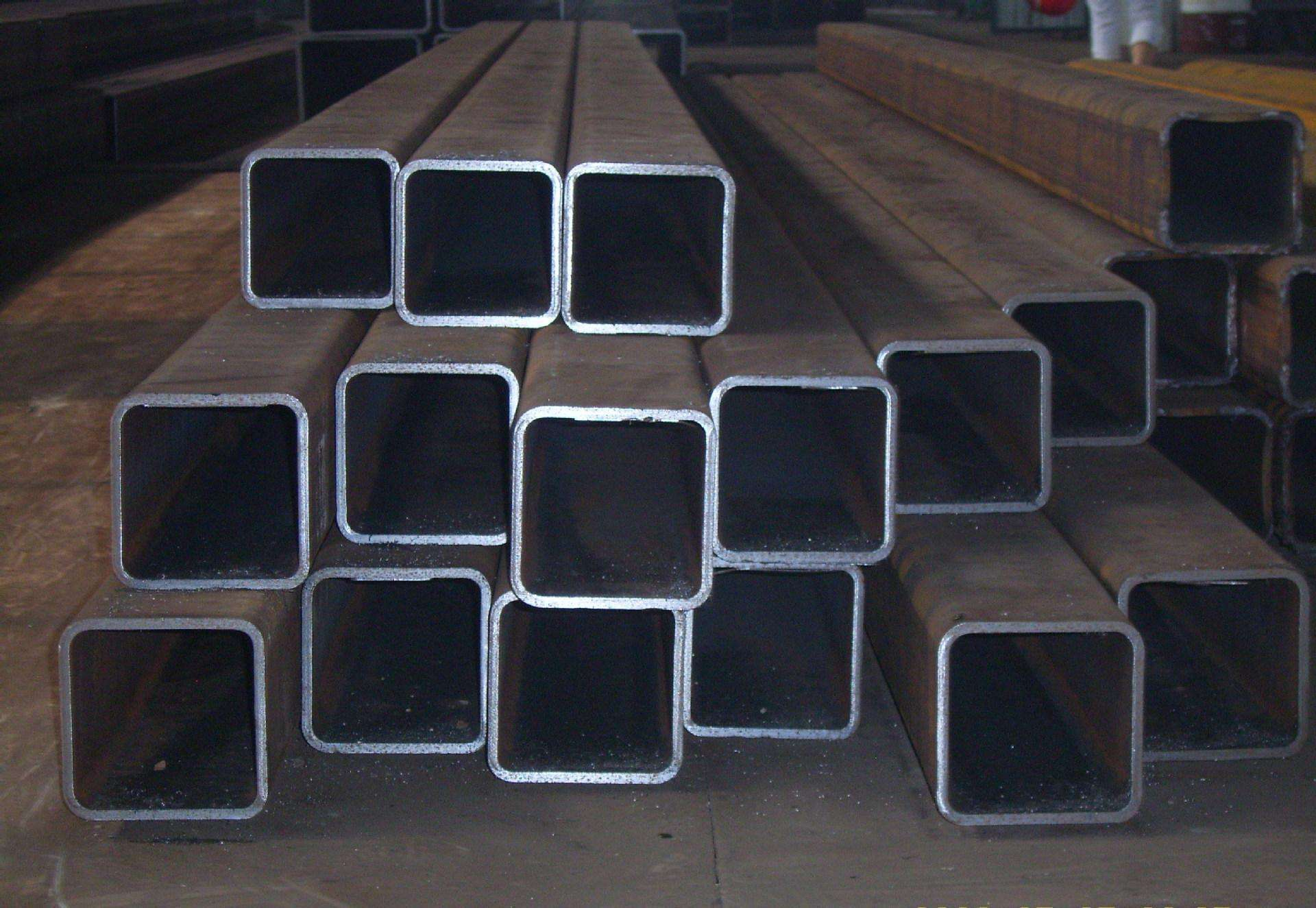

Welded pipe is a common material in gas pipeline. Welded pipe whose diameter is larger than 426 mm (or 508 mm) is generally called large diameter welded pipe. According to the way of pipe forming, it can be divided into spiral welded pipe and straight welded pipe. Spiral welded pipe is made by coiling low carbon structural steel or low alloy structural steel strip into billet according to a certain angle of helix (also known as forming angle), and then welding the pipe seam. It can produce large diameter steel pipe with narrow strip. Spiral welded pipes are mainly spiral submerged arc welded pipes (SSAW), which are widely used in the construction of various gas pipelines in China. Their specifications are expressed by external diameter * wall thickness. Spiral welded pipe has one-sided welding and two-sided welding. Welded pipe should ensure that hydraulic test, tensile strength and cold bending properties of weld seam meet the requirements. 直縫焊管是將熱軋板卷(juàn)經過成型機成(chéng)型後,使鋼卷變形為圓滑的圓筒狀,利用高頻電流的集膚效應和鄰近效應或焊劑層下燃燒的電弧進行焊接,使管坯邊緣加熱熔化,並在一定的擠壓(yā)力作(zuò)用下熔合,經最終冷卻成型。其中管坯邊緣利用高頻電流熔化的被稱為高頻直縫(féng)焊管(guǎn)(ERW),利用電(diàn)弧(hú)熔化的(de)被稱為直縫(féng)埋弧焊管(LSAW)。

Straight seam welded pipe is formed by hot-rolled sheet coil through forming machine, so that the coil is transformed into a smooth cylindrical shape, using skin effect and proximity effect of high frequency current or arc burning under flux layer to weld, so that the edge of the billet is heated and melted, and fused under certain extrusion force, and finally cooled and formed. The billet edge melted by high frequency current is called high frequency straight seam welded pipe (ERW), and the tube edge melted by arc is called straight seam submerged arc welded pipe (LSAW).

直縫(féng)焊管主要原料是低碳鋼熱軋板卷、熱軋帶,在石油、冶金、建築、煤礦、港口、機械等行業廣泛用於石油天然氣(qì)輸送、低壓水煤氣輸送、礦用流體輸送、帶式輸送機托輥、汽車傳動軸等等。

The main raw materials of straight seam welded pipe are low carbon steel hot rolled sheet coil and hot rolled strip. It is widely used in petroleum, metallurgy, construction, coal mine, port, machinery and other industries for oil and gas transmission, low pressure water gas transmission, mine fluid transmission, belt conveyor roller, automobiles transmission shaft, etc.