由於(yú)生產的需求,和降低生產與製造的成本的緣故,許多(duō)客戶由原本的冷拔無縫鋼管采購改(gǎi)為精密鋼(gāng)管。下邊就咱們就(jiù)來理解下精密鋼管的優點和劣勢:精密鋼管優點(diǎn):

Due to the demand of production and the reduction of production and manufacturing costs, many customers have purchased precision steel tubes instead of cold-drawn seamless steel tubes. Next, let's understand the advantages and disadvantages of precision steel pipe: the advantages of precision steel pipe:

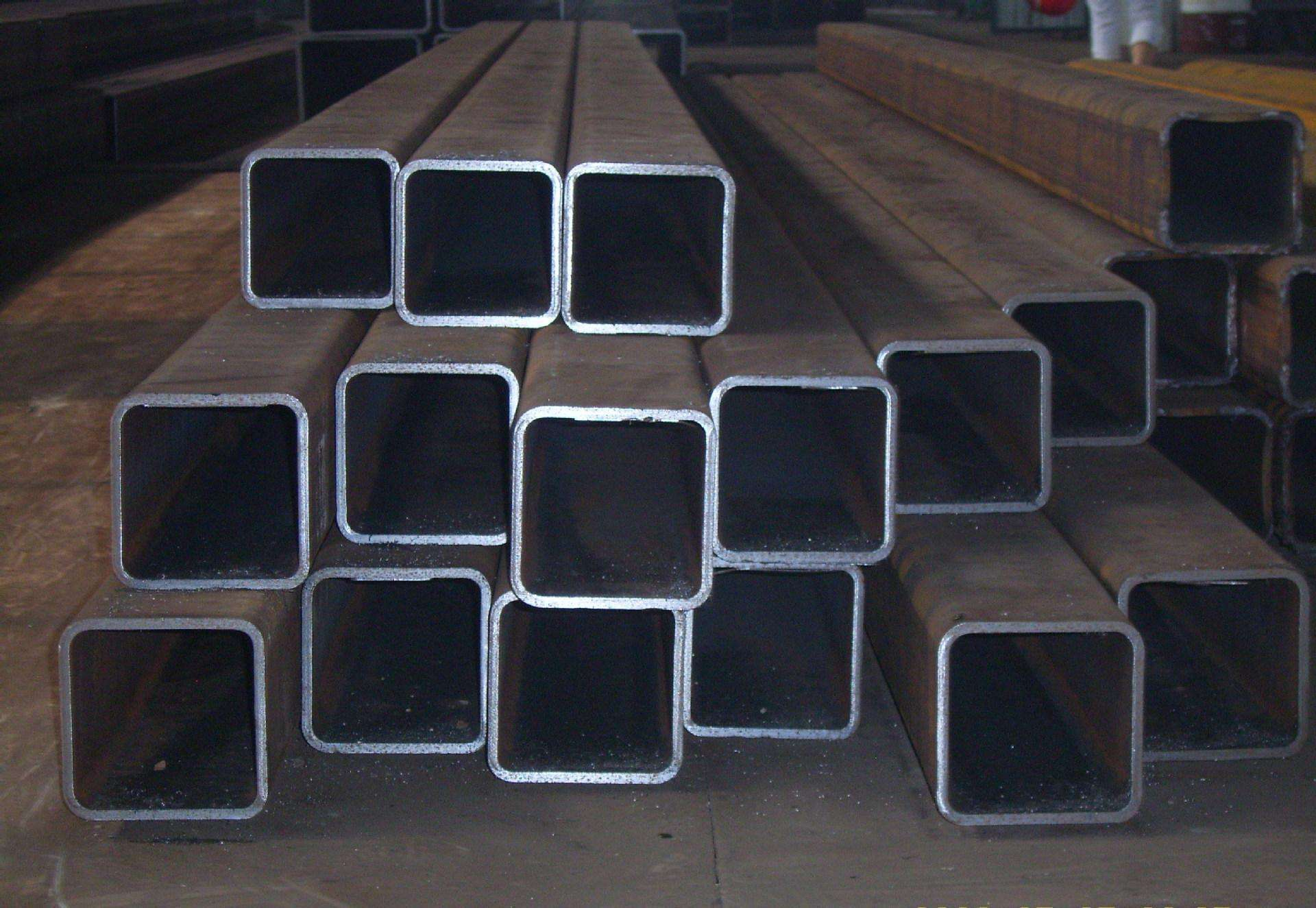

1、精密無縫管成型速度快,生產(chǎn)產量高。且不(bú)損壞塗層,可以製成多種(zhǒng)多樣的截麵模(mó)式,以適用條件的需求。

1. Precision seamless pipe has fast forming speed and high production output. Without damaging the coating, various cross-section modes can be made to meet the requirements of applicable conditions.

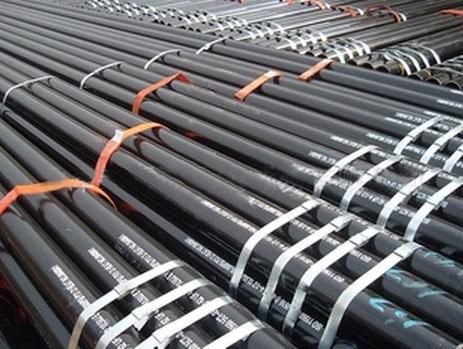

2、冷軋(zhá)工藝可以使精密鋼管產生巨大的拉升變形,進而改善了(le)精(jīng)密鋼管的屈服點。

2. Cold rolling process can make the precise steel tube produce huge pull-up deformation, and then improve the yield point of the precise steel tube.

3、精密鋼管的準確度高,使用(yòng)戶減小了廢(fèi)物的產生。

3. Precision steel pipe has high accuracy, which reduces waste generation for users. 精密鋼管劣勢:

Precision steel tube disadvantage:

1、精密(mì)無縫管截麵存在剩餘應力,對(duì)精密鋼管的總體和(hé)局部屈曲的特點產生影響;

1. Residual stress exists in the section of precision seamless pipe, which affects the overall and local buckling characteristics of precision steel pipe.

2、精密鋼管的截麵的自由扭轉剛度比較低;

2. The free torsional stiffness of the precise steel tube section is relatively low.

3、冷軋精(jīng)密鋼管的成型壁厚較小,經受局(jú)部性的集中負荷運載的能力不足。

3. The cold-rolled precision steel tube has a smaller wall thickness and insufficient capacity to withstand local concentrated load.