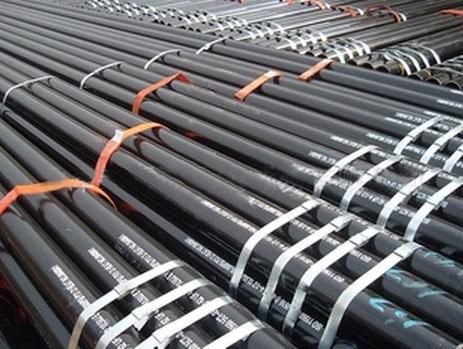

在焊管生產過程中,隻要進行焊接,焊管表麵(miàn)就會產生應力和變形,隻是程度不同罷了。焊管在(zài)焊接過程(chéng)中產生的焊接應力和(hé)各種變形,往往使焊接產品質量下降,甚(shèn)至造成裂紋。焊接變形造成焊件尺寸,形狀的變化,這種變化超過一定的數值後(hòu),可(kě)能無法與(yǔ)其他焊管連接或沒(méi)有足夠的加工餘量無法進行切削加(jiā)工。下麵我們(men)說下應力和變形。

In the production process of welded pipe, as long as welding is carried out, stress and deformation will occur on the surface of welded pipe, but to varying degrees. Welding stress and various deformations of welded pipes in the welding process often cause the quality of welded products to decline, and even cause cracks. Welding deformation results in the change of weld size and shape. If the change exceeds a certain value, it may not be able to connect with other welded pipes or not have enough machining allowance for cutting. Now let's talk about stress and deformation. 首先是焊管的表麵(miàn)應力,當材料在外力作用下不能產生位移時,它的(de)幾何形狀和尺寸將發生變化,這種形(xíng)變就稱為應變。材料發生(shēng)形變時(shí)其內部產生了大小相等但方向相反的反作用力抵抗外力,把分布內力在一點的集度稱為應力,應力與微麵積的乘積即為內力,或(huò)物體由(yóu)於外因(受力(lì)、溫度變化等)而變形時,在物體(tǐ)內各部分之間產生相互作用的內力,以抵抗這種外因(yīn)的作用,並(bìng)力圖使物體從變形後的位置回複到變(biàn)形前的位置。

First is the surface stress of welded pipe. When the material can not produce displacement under external force, its geometry and size will change. This deformation is called strain. When a material is deformed, it produces internal reaction force of equal size but opposite direction to resist external force. The concentration degree of distributed internal force at a point is called stress. The product of stress and micro-area is internal force, or when the object is deformed by external factors (force, temperature change, etc.), the internal force interacts among various parts of the object to resist the effect of external factors. Make the object return from the position after deformation to the position before deformation.

從力學角度來講,變形是指結構(或其一(yī)部分)形狀的改變。任何結構都是由可變(biàn)形固體材料組成,在外力作用下將會產(chǎn)生變形和位移。

From a mechanical point of view, deformation refers to the change of the shape of a structure (or part of it). Any structure is composed of deformable solid materials, which will produce deformation and displacement under the action of external forces.

在焊管生產過(guò)程(chéng)中,即使能(néng)矯正,如機(jī)械或火(huǒ)焰矯正(zhèng)過(guò)來,這也不僅費時費力,而且又增加(jiā)了焊管的附加應力,對構建使用不利、由此,我們必(bì)須對焊接應力和變形的產(chǎn)生原因、大小程度以及如何減小和避免焊接應力和(hé)變形進行了解。

In the production process of welded pipe, even if it can be corrected, such as mechanical or flame correction, it will not only take time and effort, but also increase the additional stress of welded pipe, which is unfavorable for construction and use. Therefore, we must understand the causes, magnitude and extent of welding stress and deformation, and how to reduce and avoid welding stress and deformation.